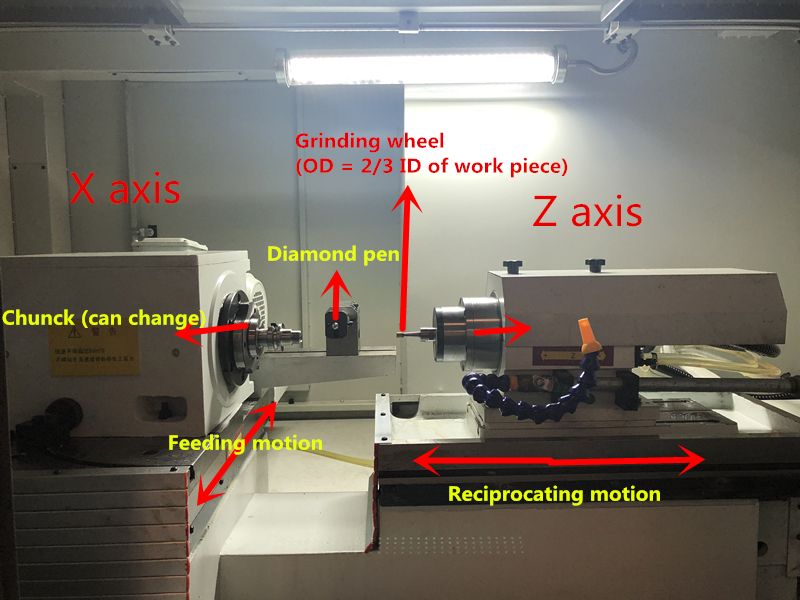

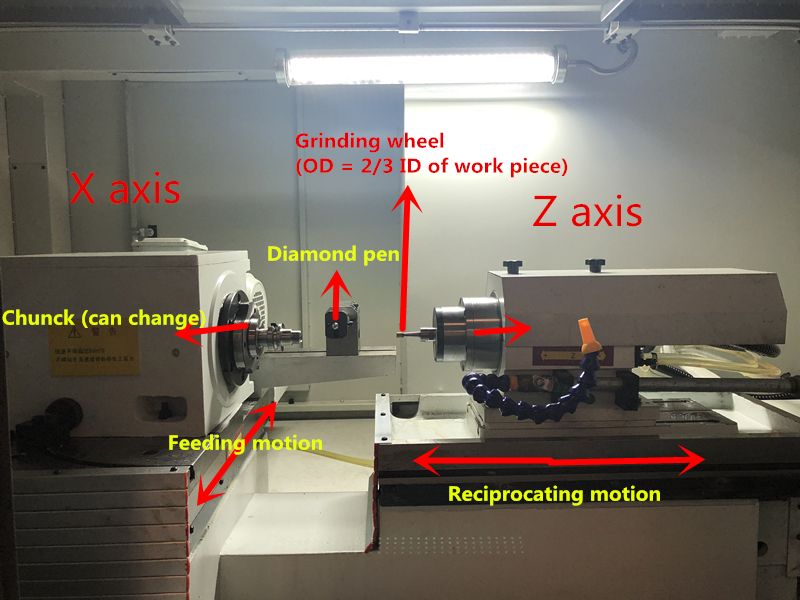

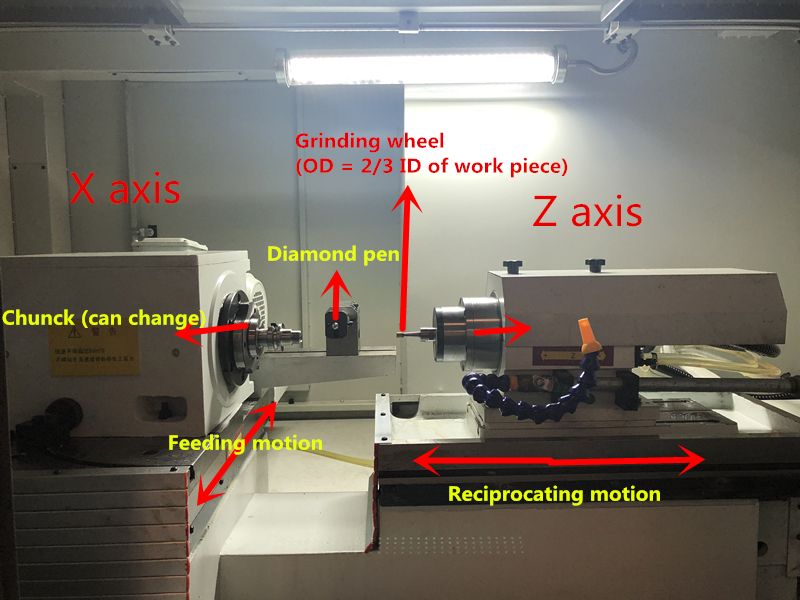

MK215 CNC Internal grinding machine tool

IMK215 CNC Internal grinding machine

Main characteristics

This machine tool is mainly used for grinding of internal hole, stepped hole, internal tapered hole and end face of work piece

The body of machine tool adopts the cast iron for casting with compact structure, good stability and strong rigidity.

The setting up and adjusting of the parameters of machine tool utilizes the touch screen form which can achieve man-machine dialog with the convenient and intuitive operation.

The machine tool adopts servo motor, and drives the ball screw movement through the coupler. The guide rail uses the cross intersection type of the roller steel guide rail with high precision and good rigidity.

The machine tool has the whole sealing housing that can ensure the safety of the use.

The clamps of the machine work include three jaw chuck, pneumatic clamp, hydraulic clamp, film clamp and other clamps which are optional for users.

The grinding wheel spindle adopts the high speed electric spindle which is controlled by the static frequency converter to achieve stepless speed regulating.

Specification parameter list

Items | parameter (MK215) |

Hole diameter of grinding (mm) | Φ5-Φ50 |

Maximum grinding depth (mm) | 80 |

Turning diameter of the work piece (mm) | inside the cover (mm) | Φ180 |

outside the cover (mm) | Φ220 |

Maximum rotary angle of head (°) | 30° |

Rotation speed of work piece (r/min) | 0-800 stepless |

Rotation speed of grinding wheel (r/min) | 0-60000 (stepless) |

Total power of machine tool (kw) | 6.75 |

Power of servo motor of x-ais (kw) | 1 |

Resolution of X axis (mm) | 0.001 |

Maximum stroke of X ais (mm) | 80 |

Power of servo motor of Z axis(Kw) | 1 |