November 17,

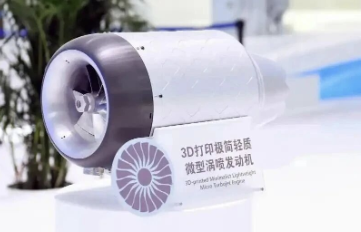

Aero Engine Corporation of China(AECC) made its debut at the Dubai International Airshow by showcasing a 3D-printed turbojet engine. The focus of attention was AECC's 3D-printed KP16-3D, a minimalist, lightweight micro-turbojet engine with a thrust level of 160 kilograms. This engine employs multi-disciplinary topology optimization and 3D printing technologies, featuring integrated design of components. Weighing only 20 kilograms (suitable for platforms such as drones), it meets the market's demand for low-cost and lightweight aviation power, marking a new stage in the application of 3D printing in the field of high-end aviation equipment.

November 18, the Weilali New Materials Research Institute (Nanjing) Co., Ltd. was officially inaugurated. The institute focuses on the research and development of strategic new materials for additive manufacturing (such as high-temperature alloys, titanium alloys, aluminum alloys, etc.) and intelligent new equipment.

November 21, data from the National Bureau of Statistics showed that from January to October 2025, the cumulative output of metal cutting machine tools reached 720,000 units, a year-on-year increase of 14.8%; the output in October alone was 70,000 units, up 6.2% year-on-year. The market demand for the machine tool industry continues to warm up. In the first three quarters of 2025, the output of 3D printing equipment products grew by 40.5% year-on-year, a rate much higher than that of industrial robots (18.2% growth during the same period) and new energy vehicles (30.1% growth during the same period). This data reflects that 3D printing technology is accelerating its popularization in fields such as industry, healthcare, and consumer goods, becoming an important support for the transformation and upgrading of manufacturing.

November 21, CHOTEST announced that its independently developed large-travel Mars Classic153012 was successfully delivered to a well-known automotive parts enterprise in Northeast China. The equipment adopts fully self-developed technology along the entire chain and can meet the precision measurement needs of large and complex workpieces such as truck drive bridge shells. Its accuracy indicators reach the advanced level of the market, achieving full-process quality monitoring from incoming inspection to production process control and finished product shipment, providing key technical support for the quality of commercial vehicle manufacturing.