Features of the machine tool performance and structure

Being a top grade CNC machine tool, MKS8332 CNC camshaft grinding machine is developed by the Company with its own design and mainly used for camshaft grinding. Based on design method of production type CNC grinding machine and non-round grinding technology, the machine tool realizes cam profile CNC linkage grinding. With strong processing flexibility, simple and reliable operation, the machine tool is of international advanced standard for its high stiffness, efficiency and reliability.

As two-axis CNC interpolation linkage is adopted for full closed-loop controlof grinding wheel feeding (X axis) and work-piece rotating (C axis), it realizes numerical control precision positioning movement of non-round cam profile, completely removes disadvantages oftraditional profilingmachine tools,suchas poor machiningflexibility, difficulty of profiling and complicated maintenance. The linear speed of CBN grinding wheel is 120m/s. Both C and X axisadopt international advanced direct driving technology, mainly used for large scale precision processing camprofileof camshaft components for internal-combustion engines. The front side of machine tool is of vertical plane without any adjustment links, convenient for erection of additional component logistical transmission line without mutual interferences, therefore it is an optimized equipment for a production line. The machine tool is designed in conformity with related requirements on safety, environment protection and human engineering as defined in the State and international standards.

With structural layout of mechatronics and integral protective cover, the machine tool is convenient for maintenance and in conformity with human engineering requirements.

Due to direct driving of hydrostatic electric spindle, CBN grinding wheel features high rotation precision, retentive precision and strong rigidity. With linear speed as high as 120 m/s, the grinding wheel is equipped with built-in dynamic balance system.

The machine realizes three-axislinkage feeding with work head (C axis) directly driven by torque motor, positioning accuracy of 0.002 degree; wheel head(X axis) directly driven by linear motor, good dynamic response, maximum speed of 40m/min; worktable(Z axis) driven by servo motor, minimum setting unit of 0.1μm and maximum speed speed of 20m/min.

With the linear speedof 120m/s, CBN grinding wheel adopts diamond roller for dressing and is provided with sonar detector so as to insure trace amount precision dressing, thus extending its service life; the roller is directly driven by the electric spindle.

The machine tool adopts an imported advanced CNC system and is provided with all-around controlling functions including grinding program changes, work-piece quality control, machine condition monitoring, fault self-diagnostics, abnormal alarm, and convenient menu type interface input.

Specifications

|

Specification |

Unit |

MKS8332 |

|

|

Maximum swiveling diameter |

mm |

Φ360 |

|

|

Distance between Centers |

mm |

1000 |

|

|

Height of center |

mm |

180 |

|

|

Maximum grinding diameter |

mm |

Φ320 |

|

|

Maximum workpiece weight between centers |

kg |

150 |

|

|

Control System |

|

FANUC310i SIEMENS840D |

|

|

Grinding wheel |

Outsidediameter |

mm |

Φ370 (CBN) |

|

Linear speed |

mm/sec |

120 |

|

|

Wheel head |

Total travel |

mm |

330 |

|

Feed speed |

mm/min |

0.05~40000 |

|

|

Minimum setting unit |

mm |

0.001 |

|

|

Oblique angle |

° |

90 |

|

|

Worktable |

Type |

|

Two layer conical degree adjusting worktable |

|

Feed speed |

mm/min |

0.05~20000 |

|

|

Minimum setting unit |

mm |

0.001 |

|

|

Work head |

Center |

|

MT. No.5 |

|

Rotating speed |

r/min |

0-200 (stepless) |

|

|

Tailstock |

Center |

|

MT. No.5 |

|

Travel of center |

mm |

60 |

|

|

Electrical system |

Power of wheel spindle motor |

Kw |

30 |

|

Thrust of wheel head feeding |

N |

1700 |

|

|

Torque of worktable feeding motor |

N.m |

22(FANUC)/27(SIEMENS) |

|

|

Torque of work head spindle motor |

N.m |

100 |

|

|

Hydraulic pump motor |

Kw |

0.75(4P) |

|

|

Motor of wheel spindle bearing lubrication pump |

Kw |

0.75(4P) |

|

|

Cubage dimension |

Hydraulic and lubricating oil tank |

L |

45 |

|

Spindle bearings oil tank |

L |

45 |

|

|

Net Weight |

kg |

11000 |

|

Working accuracy (standard test specimen)

|

Inspection item |

MKS8332 |

|

Lift error of cam profile |

±0.015 |

|

Angle offset error of adjacent cams |

±0.15° |

|

Parallelism |

≤0.01mm |

|

Coaxiality (base circle run-out) |

≤0.01mm |

|

Roughness |

Ra 0.32μm |

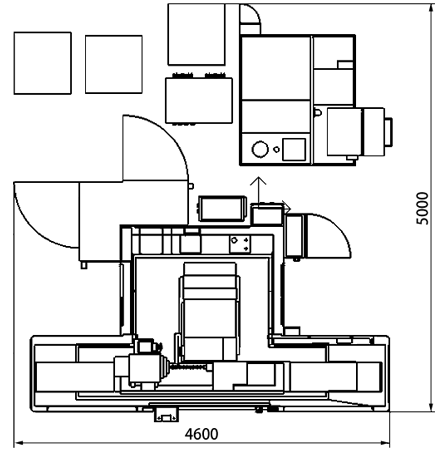

Layout plan

Specifications, precision and appearance are subject to change without notice because of constantly development of our technology.

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.