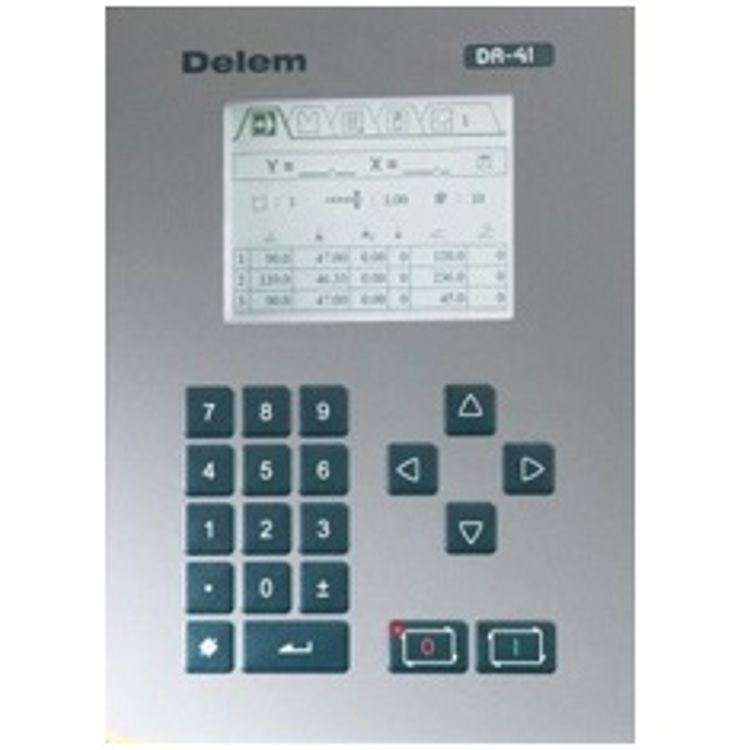

DA-41 Compact and axis control for

conventional press brake applications

The DA-41 control provides a complete solution for conventional press brake applications for 2 axes. Including the axes control for the press beam and backgauge and flexible I/O configuration, the state of the art electronics offers a versatile solution.

With its bright LCD display a clear and easy control is offered. The numerical programming, having angle, tool and material parameters on hand, can be done in a direct table overview. The bend parameters can be selected via a user-friendly cursor manipulation.

The axes control supports servo control, two-speed AC control as well as unipolar control. Depending on the application you can select either two-side positioning as well as single side positioning with spindle fault elimination.

Features

■ Bright LCD display

■ Beam stop control

■ Backgauge control

■ Angle programming

■ Tool programming

■ Retract function

■ Up to 100 programs

■ Up to 25 bends per program

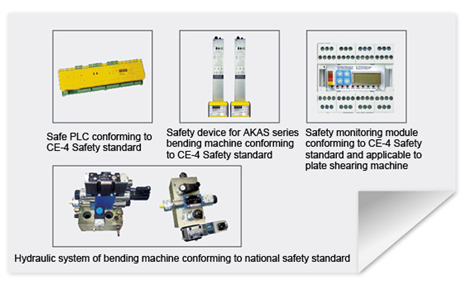

Electric control system of bending machine

Electric control system of bending machine can be customized according to customer requirements, integration of the Company E series, DA series CNC system.

Fiessler optoelectronic safety AKAS series Photo-electric Safeguarding of Press Brakes

Germany Fissler company launched the AKAS ® series bending machine safety photoelectric protection device,the AKAS ® series of transmit receivers can be selected automatically depending on the user's requirements, can also not with automatic adjustment of the LC series; F series with integrated bending machine PLC and without M series.

Features:

■ Maximum safe range for increased productivity

■ The mold can be changed automatically after adjustment

■ Adjust the response time of 2ms

■ Automatic measurement and control of safety speed

■ Supports the shell workpiece bending safety protection

FPBS Laser safety protection device dedicated to bending machine

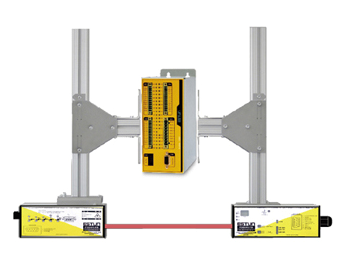

FPBS is jointly developed by Nanjing ESTUN and Germany FIESSLER Company. It is a professional safety protection device specific to Chinese safety standards for bending machine. Twenty-year experience of ESTUN in forging industry and professional development guarantee the applicability of FPBS.Germanymanufacturer guarantees the excellent quality of FPBS. FPBS can be installed on bending machine easily with the help of special installation support to protect the front part of bending machine and operator and prevent accident.

Major characteristics

■ Double-beam laser safety detection

■ Dual redundant safe output

■ Folded box mode

■ Safe speed monitoring

■ 1.5ms high-speed response

■ State and signal indicate

■ Input monitoring of safety point

Major data

Electric parameters | |

Working voltage | 24V DC, +/-20% |

Maximum working current | 0.5A at most |

Protection level | III |

Electric connection | Emitter: rapid plug Receiver: rapid plug |

Output | OSSD 1nad OSSD2; fault safety protection transistor;0.5Aat most; one circuit breaker and one leakage current monitor. FA: transistor output,0.5Aat most |

Input | FP. S1. S2: 10mA BB: 25mA |

Response time | 1.5ms, after beam is occluded and before OSSDs signal is cut off 10ms, after pedal is released or protective circuit is switched on and before OSSDs output is shut down |

Environmental parameters | |

Working environment temperature | 0℃ to50℃ |

Storage environment temperature | -25℃ to70℃ |

SAFE100 Safety control module

Safety functions

• Redundant loop, dual CPU control

• Connection fault detection

• Input fault detection Detect the fault of input channel via detecting impulse signal

• Output fault detection

• Backup and detection of key data

SAFE100 safety module is a special safety module developed subject to CE safety product standards. It has complete self-diagnosis function and input/output loops and CPU are dualredundant-structured so the safety function would not fail when single loop breaks down. It has impulse detection power so it can detect circuit fault automatically and indicate output state.

Function | Signal port | Signal mode | Action mode |

Instant stop monitoring | IN1, IN2 | NC,NC | Oil pump stops and machine tool stops running. |

Side door monitoring | IN3, IN4 | NC,NC | Slider can descend slowly (<20mm/S) |

Back door monitoring | IN07, IN08 | NC,NC | Oil pump stops and machine tool stops running. |

Pedal monitoring | IN13, IN14 | NC, NO/NO, NO | Pedals in three position. Pedal on upper position stops, pedal on middle position works and pedal on lower position stops. |

Mode monitoring | IN17, IN18 | NC, NO | Single mode, slider working normally; adjustment mode, slider slowing down in the whole course. |

Detection mode | IN15, IN16, IN19 | NC,NC, NC | Signal accesses and machine tool enters continuous detection mode. |

Safe output | O1, O2 | Dual redundant output | Instant stop and back door protection are triggered and output stops. |

Technical specification

■ Power port: 24V, 0V (system)24VO, 0VO (IO port), FG (shell grounded)

■ Safety input: I01-I20 (20mA)

■ Detection output: T1-T4 (PNP 0.5A)

■ Assistant output: OA (PNP 0.5A)

■ Safe output of transistor: O1-O4 (PNP 2A)

■ Safe output of relay: R1A, R1B; R2A, R2B (capacity: 24VDC/3A; 220VAC/3A)

■ Extension port: CO+, CO-, CI+, CI- (reserved)

■ CAN interface: CN3 (reserved)

■ RS232 interface: CN6

FPBS Special installation support

Product characteristics

• High repeated precision

• Convenient debugging

• Self-locking function of limiter in vertical direction

• No squeezing risk when out of control

• Arrow mark function of different moulds

• Function of shock absorber of integrated emitter

• High-quality structure composed of Al stainless steel

Other optional products

Germany Heidenhain grating

Features:

■ Enclosed grating

■ Ruler and scan head with anti-pollution housing rail built-in

■ The scanning head moves within the scale

■ Friction is low

■ Measuring step 5μm

■ Universal TTL level interface

■ Wide selection:220mm-920mm

■ Can be applied to a vibrating machinery

■ Installation is simple

■ Anti-vibration

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.