■ Two-axis Control

Using a drive driving two-axes motor at the same time, EDS servo drives make full use of the processing chip resources,and greatly reduce the installation space. Compared with two sets of single axis servo drive unit, it is highly cost-effective.Particularly in the requirements of two-axes synchronization,EDS servo drives can achieve better performance than two sets of single axis servo drive unit.

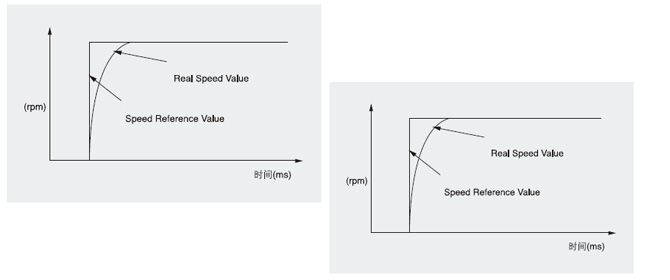

■ High Performance

■ Communication Interface

Based on Modbus protocols of RS232 interfaces, the host can be connected up to 32 servos for network control. Besides, the host can also communicate with PLC, DCS, intelligent instruments, touch screens, etc., and the centralized monitoring is implemented.

■ Single Axis Positioning Function

The 16-node single axis positioning function is built inside EDS servo drives, and a touch screen can be connected directly to the RS-232 interface on the servo drives, thus the costs go down since an intermediate PLC unit is eliminated. With the touch screen, user may program easily every node’s position, speed, acceleration and deceleration time, latency time,start point and stop point, moreover, the above info can be transmitted to the servo drive via RS-232 interface. User may select to program absolute values or incremental values and select cycle run or not. User may also use reference point search function and program the go and back speed for reference point search and in addition, it’s also available to use external signals for step changes. Actually users may develop own application programs to meet different demands on different occasions.

ESView Communication Software

With special PC softwares available, following functions are achieved:

■ Parameter:management Fast and convenient operations to parameters of both axes are available, such as editing, transmission, comparison and initialization.

■ Monitoring:Real time monitoring I/O signals of both axes, current

and history alarm records, system status.

■ Real time sampling:Real time sampling the curves of position, speed

and current facilitates the adjustment and analysis.

■ Adjusting:Fast adjustment of gains is available.Simple test is available when there’s no position or speed reference input.

- JICHUANG.COM-Machine tool weekly highlights.Week 51 of 2025 (December 15 - December 21, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.