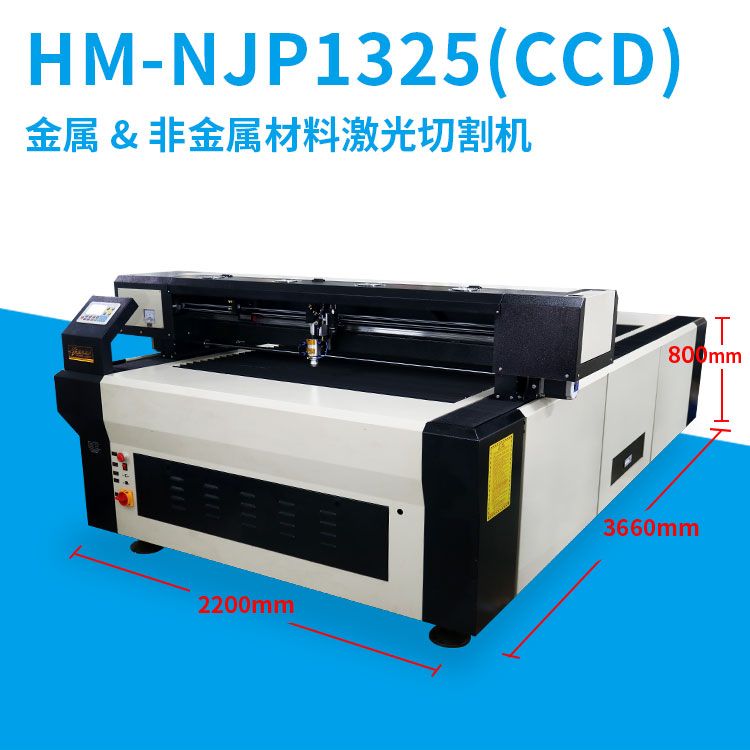

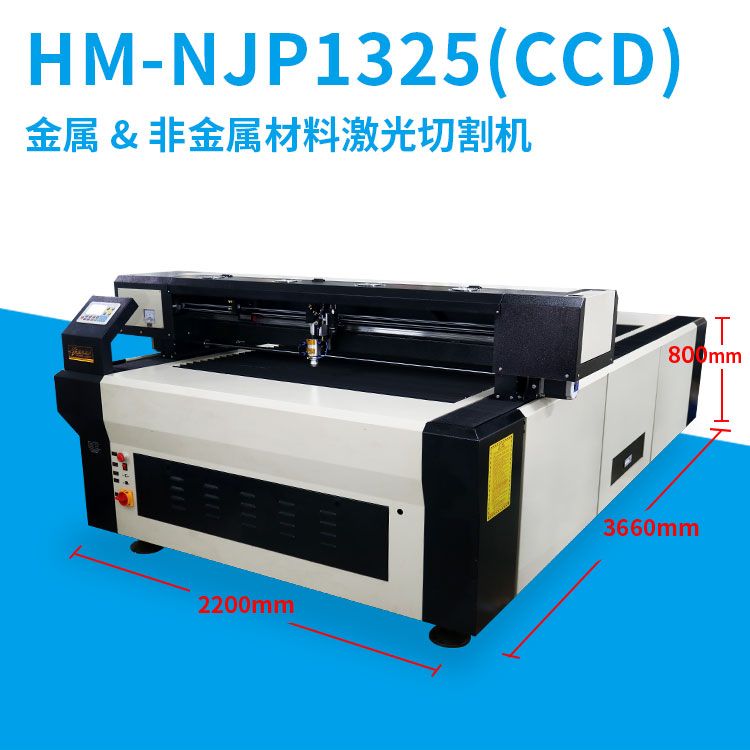

HM-NIP1325CCD: Metal and nonmetal Laser Cutting Machine

This series of models adopt DSP digital control technology, integrated design framework, stable and reliable, the latest software support and AutoCAD, CorelDraw and other CAD, CAM and various graphic processing software seamless docking, direct original output. The industry's first use of cable data interface, hot swappable, instantaneous data transfer is completed, do not take up computer resources carving, greatly improving user productivity. Chinese LCD, friendly interface, the operation is more respect.

This type of laser cutting machine is configured as high-precision motor drive components, four professional laser lens, you can make the machine speed and accuracy to the fullest; engineering design for the optical system, can improve the efficiency of the laser beam, it is specialized in carving and cutting ideal for user's choice.

Feature

1, HM-JP1325 can cut stainless steel, carbon steel, acrylic, wood and other materials. Combined with its affordable price, it is a very high cost of hybrid material cutting models.

2, Han Ma laser self-developed laser cutting optimization system, complete with independent intellectual property rights. It can maintain a stable cutting focus on high-speed movement. Anti-collision protection, and ensure the safety of the cutting head. Feature

1, HM-JP1325 can cut stainless steel, carbon steel, acrylic, wood and other materials. Combined with its affordable price, it is a very high cost of hybrid material cutting models.

2, Han Ma laser self-developed laser cutting optimization system, complete with independent intellectual property rights. It can maintain a stable cutting focus on high-speed movement. Anti-collision protection, and ensure the safety of the cutting

head.

Main Accessories

1, Metal cutting servo system.

2, Constant optical system.

3, Beijing Totten ham high CO2 laser tube.

4, Imports of steel wire belt.

5, Industrial water cooling systems.

6, Touch-screen operating system.

Technical Parameters

Machine Model: NIP1325CCD

Working Area: 1300X2500mm

Laser generator: best domestic Beijing Tottenham tube

Laser power: 150W

Cutting stroke: 1300mm * 2500mm

Cutting speed: Depending on the material and the thickness of the

Repeat positioning accuracy: ± 0.05mm

Positioning speed: 20000mm / min

Cutting thickness: ≤2mm

Power consumed: <= 4KW

Electricity demand: 220V / 50Hz / 60Hz (Direct Normal grid to meet)

Machine Weight:710kg

Dimensions: 2105mmX3180mmX1120mm

Features

• Low cost per hour laser consumes only 0.5 to 1.5 degrees.

• High-performance, best-made Beijing Totten ham laser, stable performance and long service life.

• High speed, high efficiency, cut sheets per minute up to several 2.6 m.

• the whole year warranty, the laser tube warranty nine months.

• the cutting edge of good quality, small deformation, smooth appearance and beautiful.

• free to design a variety of graphics or text instant cut, simple, flexible and convenient.

Suitable materials

Can cut a variety of sheet metal, mainly for stainless steel, carbon steel, galvanized steel, various alloy plate, rare metals and other materials quickly cut; also be used for wood products, paper, leather, cloth, Plexiglas, epoxy resin , acrylic, wool, plastic, rubber, ceramic tile, crystal, jade, bamboo products, such as cutting.

Sample