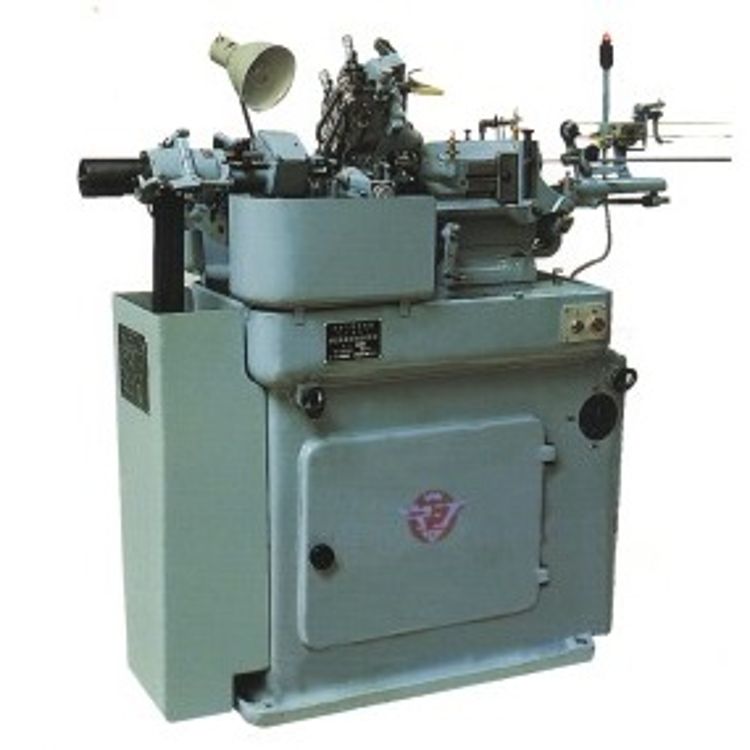

Machine features

1. The machine is equipped with 5 tool

rests which are arranged radially with center rest and are controlled

respectively by cams. The radial and axial position of tools could be adjusted

by precision screws.

2. The front bearing of spindle is high speed quill bearing and the rear

bearings are a pair of precision radial thrust bearings. The belt on the

spindle adopt offload structure which improve the working accuracy of spindle.

3. On the camshaft, there are cams to control the motion of various device.

There is a acceleratingdevice for camshaft transmission.

Specification

|

No. |

Item |

CM1113 |

unit |

|

|

1 |

Max. working diameter |

13 |

mm |

|

|

2 |

Max. working length |

80 |

mm |

|

|

3 |

steps for spindle speed |

21 |

steps |

|

|

4 |

spindle speed |

600-6000 |

rpm |

|

|

5 |

camshaft speed |

0.031-10.5 |

rpm |

|

|

6 |

steps for camshaft speed |

32 |

steps |

|

|

7 |

tool dimension |

- |

- |

|

|

8 |

numbers of tool rest |

- |

- |

|

|

9 |

motor power |

2.2 |

kW |

|

|

10 |

motor speed |

940 |

rpm |

|

|

11 |

overall dimension |

with stock support |

4737×870 |

mm |

|

without stock support |

1867×870 |

mm |

||

|

12 |

net weight (without attachment) |

1000 |

Kg |

|

- JICHUANG.COM-Machine tool weekly highlights.Week 51 of 2025 (December 15 - December 21, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.