|

MODEL |

WIDTH(mm) |

LENGTH(m) |

|

XK2312-5X |

1200 |

2 、2.5 、3 、4 、5 、6 、8、10、12、14、16、20、24... |

|

XK2316-5X |

1600 |

2 、3 、4 、5 、6 、8、10、12、14、16、20、24... |

|

XK2320-5X |

2000 |

3 、4 、5 、6 、8、10、12、14、16、20、24... |

|

XK2325-5X |

2500 |

4 、5 、6 、8、10、12、14、16、20、24... |

|

XK2330-5X |

3000 |

4 、5 、6 、8、10、12、14、16、20、24... |

|

XK2340-5X |

4000 |

5 、6 、8、10、12、14、16、20、24... |

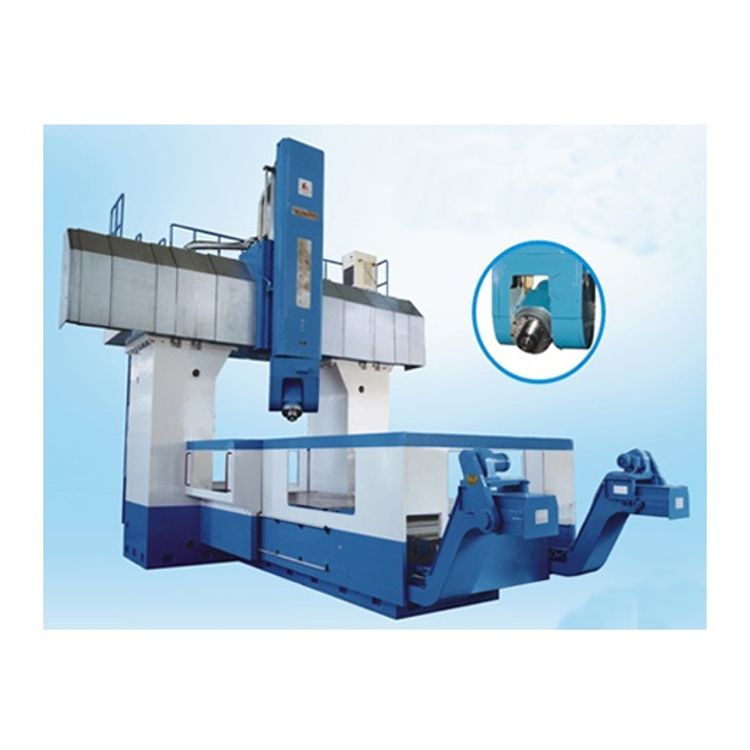

APPLICATION

This machine is planner-type machining center with 5 axes. The machine with universal milling head can process ( simultaneous control of 5 axes), milling, boring, drilling at any angle in space during once clamping. It is widely used in manufacturing industries such as ship aircraft, mould automobile, and etc.

CHARACTERISTICS

●Reasonable and advanced structure, and beautiful configuration.

Longitudinal guideway adopts two guideways (or many guideways) distribution,

cross guideway adopts combined structure of double dislocation linear guideway

and slide guideway. The up-down guideway with large combined length stable

structure, high rigidity, large bearing, well anti-friction, high sensitivity.

●CNC system and AC Servo motors: Siemens (Germany), Rexroth

(Germany), Fanuc (Japan), Fagor ( Spain) or Huazhong system (China).

●C axis on automatic universal milling head can rotate ±370°and Axis

can swivel ±100°.It can realize simultaneous controls of 5 axes.

●Double-hydraulic balance is used in up-down parts to guarantee its

stable and reliable movement.

●Automatic central lubrication with fixed time and quantity.

●Equipped with enclosed hood.

●With automatic chip conveyer.

●Domestic or imported automatic universal milling head is optional.

●The vertical travel of ram (800, 1000, 1250, 1500, 2000) mm, spindle

motor power, rated torque of Spindle, spindle speed and otherwise is optional.

|

Name |

unit |

XK2316/3-5X |

XK2320/4-5X |

|

|

Working table(W×L) |

mm |

1600×3000 |

2000×4000 |

|

|

T-slot (Number x Width x Pitch) |

mm |

9×28×160 |

9×28×200 |

|

|

Longitudinal travel of table |

mm |

3000 |

4000 |

|

|

|

Cross |

mm |

2200 |

2500 |

|

Vertical |

mm |

1000 |

1000 |

|

|

Distance between spindle nose and table surface |

mm |

80~1080 |

||

|

Spindle Motor power |

kw |

28/39(S1-100%/S6-60%) |

||

|

Spindle speeds |

rpm |

100~12000(Infinitely variable) |

||

|

torque of spindle |

N·m |

89/124 |

||

|

Spindle taper |

BT40( HSK63A is optional) |

|||

|

Axis C rotation |

±370° |

|||

|

Axis A rotation |

±100° |

|||

|

A, C Axis speeds |

rpm |

0~5 |

||

|

Rapid speed of three directions |

mm/min |

X、Y、Z:10000 |

||

|

Feed speed of three directions |

mm/min |

X、Y、Z:1-8000 |

||

|

Positioning accuracy |

mm |

±0.010/1000 |

||

|

Reset accuracy |

mm |

0.01 |

||

|

Max. bearing weight of table |

kg |

8000 |

10000 |

|

|

Net weight |

kg |

58000 |

78000 |

|

|

Overall dimension (L×W×H) |

mm |

8800×4700×4300 |

10800×5800×4300 |

|

- JICHUANG.COM-Machine tool weekly highlights.Week 51 of 2025 (December 15 - December 21, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.