Features of the machine tool performance and structure

Based on our years experience over designing and manufacturing CNC grinding machines and digested international advanced technology, B2-K3000 series high precision complex grinding center is a high grade CNC machine tool of advanced international level, innovated and developed by our company with proprietary intellectual property rights.

With advanced flexible complex processing technology adopted, the machine tool

is of multiple grinding wheel combination type formed series. Within one

clamping, different parts of a work-piece such as cylindrical and

internalsurface, end face, conical surface, non-round face and curved surface

can be subject to finish simultaneously. As a result, the traditional process

method to grind a work-piece with multiple machine tools in sequence is totally

substituted. The machine tool features high processing precision, efficiency

and flexibility and is suitable for precision machining operations in military

industry, aviation, cutter, measuring equipment, machine tool, automobile and

many other fields.

With a rational layout and integral protective cover, the machine tool is convenient for maintenance and in conformity with human engineering requirements.

With artificial granite bed being adopted, the advantages of good vibration absorbing ability, high rigidity and good heat stability are obtained.

Integrated hydrostatic, hydrodynamic and electrically operated spindle in wheel head, external cylindrical grinding wheel, end face external cylindrical grinding wheel and internal cylindrical grinding wheel can be arranged simultaneously. With the combination of above grinding wheels, the process demand of users will be maximally met.

Up to seven axes controlled by CNC system (four linear axes and three revolving axes), multiple process quick and flexible grinding operation can be realized.

Adopted linear electric motor (or servo motor) + closed high precision guide way for the movement of wheel head (X-axis), the accuracy, sensitivity and high responsiveness of feeding are ensured in the grinding operation. Equipped AC servo motor - ball-screw driving system for the movement of worktable (Z-axis), torque motor (or servo motor) for the rotation of wheel head (B-axis) in which its positioning accuracy reaches ±3″, the accurate transposition of multi grinding wheel is ensured, meanwhile, the interlink movement of X-Z-B axis and abnormity cylindrical surface (curved surface) grinding also can be realized.

Adopted torque motor, angle encoder drive mode and high precision rolling bearing shafting in the workpiece rotation system (C-axis), high rotation accuracy and dynamic response is obtained. By the interlink movement of C-X axis, non-circular and eccentric circle grinding are also achieved.

Equipped with servo driving transposition long stroke tailstock (W1-axis) and servo driving transposition workhead (W2-axis), it is contributed to realize rapid, flexible workpiece shifting and automatic loading and unloading of the machine tool.

Multi type diamond dressor (installed behind the workhead) can be selected, thus the accurate CNC dressing and auto-compensation is realized.

Equipped with active measuring device provided by international leading manufacturer, fully closed-loop controlling high precision grinding operation is realized.

Specifications

|

Specification |

Unit |

B2-K3020 |

B2-K3032 |

|

|

Maximum swiveling diameter |

mm |

Φ220 |

Φ340 |

|

|

Distance between centers |

mm |

1000 |

1500 |

|

|

Height of center |

mm |

180 |

180 |

|

|

Maximum grinding diameter |

mm |

Φ200 |

Φ320 |

|

|

Range of inner hole grinding |

mm |

Φ13~Φ80 |

Φ16~Φ120 |

|

|

Maximum workpiece weight between centers |

kg |

100 |

||

|

Control system |

|

FANUC SIEMENS |

||

|

Number of grinding wheels deployed |

|

Three (cylindrical grinding wheel, end face cylindrical grinding wheel and internal grinding wheel) |

||

|

Wheel head (X-axis) |

Feed speed |

mm/min |

0.05~5000 |

|

|

Minimum setting unit |

mm |

0.001 |

||

|

Worktable (Z-axis) |

Type |

|

Two layer conical degree adjusting worktable |

|

|

Feed speed |

mm/min |

0.05~5000 |

||

|

Minimum setting unit |

mm |

0.001 |

||

|

Work head |

Center |

|

MT.No.5 |

|

|

Rotating speed |

r/min |

30-300 (stepless) |

||

|

Tailstock |

Center |

|

MT.No.4 |

|

|

Travel of center sleeve |

mm |

35 |

||

|

Net weight |

kg |

10000 |

12000 |

|

Working accuracy (standard test specimen)

|

Inspection item |

B2-K3020 |

B2-K3032 |

|

Roundness (excircle/inner circle) |

0.001mm / 0.0015mm |

|

|

Consistency of the longitudinal section diameter |

0.002mm |

|

|

Roughness |

Ra 0.01μm (longitudinal grinding);Ra 0.32μm (plunge cutting);Ra 0.63μm (end face grinding) |

|

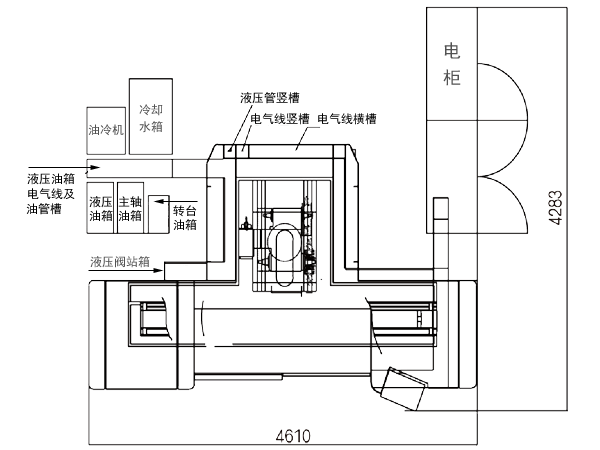

Layout plan

Specifications, precision and appearance are subject to change without notice

because of constantly development of our technology.

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 47 of 2025 (November 17 - November 23, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.