Features of the machine tool performance and structure

Adapted to features of usage demands of domestic users, B2-K1015 and B2-K1014 CNC (universal) cylindrical grinding machines are universal and economic CNC products adopting mature functional modules and parts. They are characterized by compact structures, convenient operations, reliable quality, high cost efficient performance and etc. The machines are suitable for usages in workshop dedicated for batches and small & medium-sized volume of productions, and they basically meet the requirements of high accuracy, high efficiency and flexibility needed for modern production.

With the structural layout of mechatronics and a working area protection shield or an integral protective cover (B2-K1015), the machine tool is convenient for maintenance and in conformity with human engineering requirements.

With a structure of sleeve type large-taper hydrodynamic shafting adopted for the grinding wheel spindle, the machine tool features on its adoption of the immerse oil type lubrication, high rotary precision and good rigidity.

With two-axis linkage movement, the machine tool is equipped with worktable (Z axis) and a wheel head (X axis) driven by AC servomotor and ball screws.

The machine tool adopts a pre-fixed diamond dresser, thus realizing precise CNC dressing and automatic compensation.

The machine tool is provided with an imported or a domestic active measuring device, thus realizing the closed-loop control of grinding process.

The machine tool adopts an imported or a domestic CNC system and fully absorbs advanced technologies for modern NC typecylindrical grinding machines.

Specifications

|

Specification |

Unit |

B2-K1015 |

B2-K1014 |

|

|

Maximum swiveling diameter |

mm |

Φ220 |

||

|

Distance between Centers |

mm |

500 |

||

|

Height of center |

mm |

125 |

||

|

Maximum grinding diameter |

mm |

Φ200 |

||

|

Range of internal grinding |

mm |

|

Φ13~Φ80 |

|

|

Maximum workpiece weight between centers |

kg |

50 |

||

|

Control System |

|

KND/Mitsubishi E60 |

||

|

Grinding wheel (max) |

OD × W × ID |

mm |

Φ400×(32~50)×Φ203 |

|

|

Linear speed |

mm/sec |

35/45 |

||

|

Wheel head |

Total travel |

mm |

135 |

|

|

Feed speed |

mm/min |

0.1~4000 |

||

|

Minimum setting unit |

mm |

0.001 |

||

|

Worktable |

Type |

|

Two layer conical degree adjusting worktable |

|

|

Feed speed |

mm/min |

0.1~4000 |

||

|

Minimum setting unit |

mm |

0.001 |

||

|

Work head |

Center |

|

MT. No.4 |

|

|

Rotating speed |

r/min |

30-300(stepless) |

||

|

Tailstock |

Center |

|

MT. No.4 |

|

|

Travel of center |

mm |

25 |

||

|

Electrical system |

Power of wheel spindle motor |

Kw |

4 |

|

|

Torque of wheel head feeding motor |

N.m |

14 |

||

|

Torque of worktable feeding motor |

N.m |

9 |

||

|

Power of work head spindle motor |

Kw |

0.75(6P) |

||

|

Hydraulic pump motor |

Kw |

0.75(4P) |

||

|

Cubage dimension |

Hydraulic oil tank + lubricating oil tank |

L |

30 |

|

|

Net weight |

kg |

2100 |

||

Working accuracy(standard test specimen)

|

Inspection item |

B2-K1015 B2-K1014 |

|

Roundness |

0.002mm- Superior to national standard |

|

Consistency of the longitudinal section diameter |

0.005mm |

|

Roughness |

Ra 0.16μm (longitudinal grinding);Ra 0.32μm (plunge-cut grinding) |

Special accessories (For special orders)

|

No. |

Name |

Code |

Remark |

|

1 |

Open centre rack |

M1432C-8A |

|

|

2 |

Closed centre rack |

M1432C-8B |

|

|

3 |

Four-jaw chuck |

|

|

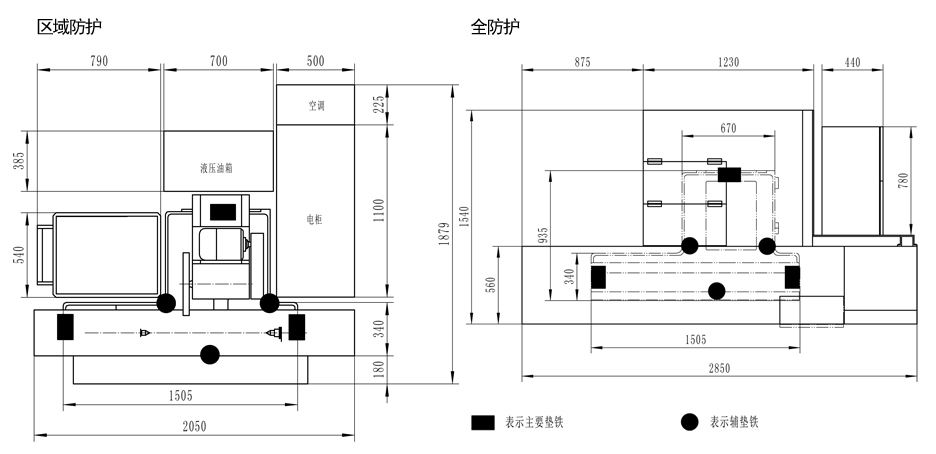

Layout plan

Specifications, precision and appearance are subject to change without notice because of constantly development of our technology.

- JICHUANG.COM-Machine tool weekly highlights.Week 51 of 2025 (December 15 - December 21, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.