Features of the machine tool performance and structure

As the high end CNC machine products, MGK1320 and MGK1420 CNC (universal) cylindrical grinding machines are independently developed on the basis of applying new technologies and rich experience of designing and manufacturing CNC grinding machines. Characterized by universalization, high-degree modularization, high rigidity, high efficiency, high adaptability, high precision, easy to operate and reliable performance,these machines are suitable for small-lot productions in workshops of military industries, aviation industry, aerospace industry and common precision machining.

With structural layout of mechatronics and integral protective cover, the machine tool is convenient for maintenance and in conformity with human engineering requirements.

With a sleeve type hydrostatic/hydrodynamic mainshaftingadopted for the grinding wheel spindle, the machine tool features on the high rotary precision and good rigidity.

With two-axis linkage feeding, the machine tool is equipped with worktable (Z axis) and wheel head (X axis) drivenbyAC servomotor and ball screws. The minimum setting unit is 0.1μm.

The machine tool can be provided with various types of diamond dressers (installed on the rear side of the work head) according to the needs of customers, thus realizing precise numerical control dressing for complex wheel profileand automatic compensation.

The machine tool is provided with an imported or a domestic active measuring device, thus realizing the closed-loop control of grinding process.

The machine tool adopts an imported advanced CNC system and is provided with all-around controlling functions including grinding program changes, work-piece quality control, machine condition monitoring, fault self-diagnostics, abnormal alarm, and convenient menu type interface input.

Specifications

|

Specification |

Unit |

MGK1320 |

MGK1420 |

|

|

×750 |

×750 |

|||

|

Maximum swiveling diameter |

mm |

Φ220 |

||

|

Distance between Centers |

mm |

750 |

750 |

|

|

Height of center |

mm |

160 |

||

|

Maximum grinding diameter |

mm |

Φ220 |

||

|

Maximum workpiece weight between centers |

kg |

100 |

||

|

Control System |

|

FANUC SIEMENS |

||

|

Grinding wheel (max) |

OD×W×ID |

mm |

Φ500×75×Φ203 |

|

|

Linear speed |

mm/sec |

35 |

||

|

Wheel head |

Total travel |

mm |

277 |

|

|

Feed speed |

mm/min |

0.1~5000 |

||

|

Minimum setting unit |

mm |

0.001 |

||

|

Worktable |

Type |

|

Two layer conical degree adjusting worktable |

|

|

Feed speed |

mm/min |

0.1~5000 |

||

|

Minimum setting unit |

mm |

0.001 |

||

|

Work head |

Center |

|

MT. No.4 |

|

|

Rotating speed |

r/min |

30-300 (stepless) |

||

|

Internalgrinding |

Power of motor for internal grinding |

Kw |

|

0.55 |

|

Range of internal grinding |

mm |

|

Φ13~Φ80 |

|

|

Max. length of internal grinding |

mm |

|

125 |

|

|

Max .workpiece weight be held by chuck |

kg |

|

30 |

|

|

Tailstock |

Center |

|

MT. No.4 |

|

|

Travel of center |

mm |

60 |

||

|

Electrical system |

Power of wheel spindle motor |

Kw |

7.5 |

|

|

Torque of wheel head feeding motor |

N.m |

8(FANUC)/16(SIEMENS) |

||

|

Torque of worktable feeding motor |

N.m |

12(FANUC)/16(SIEMENS) |

||

|

Power of work head spindle motor |

Kw |

0.75Kw variable frequency motor/1.1Kw variable frequency motor |

||

|

Hydraulic pump motor |

Kw |

0.75(4P) |

||

|

Motor of wheel spindle bearing lubrication pump |

Kw |

0.75(4P) |

||

|

Cubage dimension |

Hydraulic and lubricating oil tank |

L |

45 |

|

|

Spindle bearings oil tank |

L |

45 |

||

|

Net Weight |

kg |

6000 |

6500 |

|

Working accuracy(standard test specimen)

|

Inspection item |

MGK1320/MGK1420 |

|

Roundness |

0.0005mm |

|

Consistency of the longitudinal section diameter |

0.003mm |

|

Roughness |

Ra 0.04μm (longitudinal grinding);Ra 0.2μm (plunge-cutgrinding) |

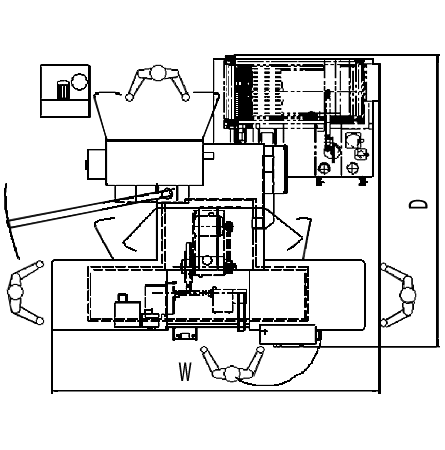

Layout plan

|

Model |

W mm |

D mm |

|

MGK1320 x 750 |

3900 |

3700 |

|

MGK1420 x 750 |

3900 |

3700 |

Specifications, precision and appearance are subject to change without notice

because of constantly development of our technology.

- JICHUANG.COM-Machine tool weekly highlights.Week 51 of 2025 (December 15 - December 21, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 50 of 2025 (December 8 - December 14, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 49 of 2025 (December 1 - December 7, 2025)

- JICHUANG.COM-Machine tool weekly highlights.Week 48 of 2025 (November 24 - November 30, 2025)

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.